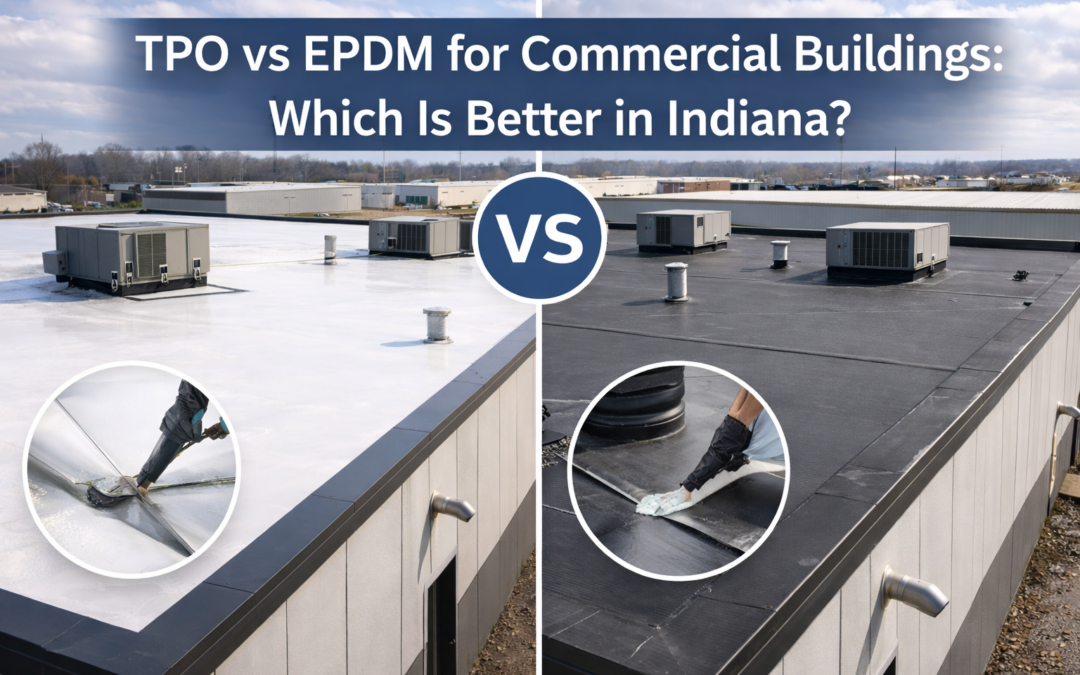

TPO vs EPDM for Commercial Buildings: Which Is Better in Indiana?

If you own a warehouse, retail center, church, or school in Indiana, you’ve likely narrowed your flat roof options to two materials:

TPO or EPDM.

Both are proven commercial roofing systems. Both are widely used across Indiana. The better choice depends on building type, exposure, maintenance expectations, and how the roof will handle freeze-thaw cycles, snow loads, and Midwest storm patterns.

Here is a clear, side-by-side breakdown tailored for commercial property owners in Lafayette and throughout Indiana.

Quick Answer: TPO vs EPDM in Indiana

Both TPO and EPDM are reliable commercial flat roofing systems.

In Indiana:

-

TPO often performs well for energy efficiency and UV reflection.

-

EPDM handles freeze-thaw cycles and extreme temperature swings very well.

The best choice depends on your building and long-term maintenance strategy.

What Is TPO Roofing?

TPO (Thermoplastic Polyolefin) is a single-ply white membrane commonly installed on warehouses and large commercial facilities.

Typical Lifespan in Indiana

20–25 years with proper installation and maintenance.

Strengths of TPO

-

Reflects sunlight and reduces heat absorption

-

Energy-efficient for large roof surfaces

-

Heat-welded seams create strong waterproof bonds

-

Resistant to UV exposure

Considerations

-

Seams must be properly welded

-

Poor drainage can shorten lifespan

-

Quality varies between manufacturers

TPO is common on distribution centers and industrial buildings in Lafayette, especially where cooling costs matter.

What Is EPDM Roofing?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber membrane, typically black, used on commercial flat roofs for decades.

Typical Lifespan in Indiana

20–30 years when maintained properly.

Strengths of EPDM

-

Excellent performance in cold weather

-

Flexible during freeze-thaw cycles

-

Durable against hail and temperature movement

-

Simple repair process

Considerations

-

Absorbs heat due to dark color

-

Seams rely on adhesive or tape systems

-

Energy efficiency may be lower without additional insulation

EPDM is often selected for buildings that experience heavy winter stress or structural movement.

How Indiana Weather Impacts TPO vs EPDM

Indiana’s climate is demanding. Lafayette sees:

-

Winter freeze and thaw cycles

-

Snow accumulation

-

Spring storm systems

-

High humidity summers

Freeze-Thaw Cycles

EPDM’s flexibility gives it an advantage during temperature swings. It expands and contracts without becoming brittle.

TPO performs well but depends heavily on seam integrity.

Snow Loads

Both systems handle snow well when properly supported. Drainage design is critical.

UV Exposure

TPO reflects sunlight and helps reduce heat buildup. This can lower cooling costs for large warehouses.

EPDM absorbs more heat unless coated or insulated.

Storm Resistance

When sourced from reputable commercial-grade manufacturers such as Malarkey Commercial Roofing and installed correctly, both systems can perform reliably in Indiana storm conditions.

Material quality and installation standards matter more than membrane color alone.

Cost Differences Between TPO and EPDM

Pricing varies by building size and roof complexity, but general trends in Indiana:

TPO

-

Slightly higher upfront installation cost

-

Lower long-term cooling expenses

EPDM

-

Often lower initial material cost

-

May require additional insulation for energy efficiency

Long-term cost depends on maintenance and inspection frequency.

A well-maintained EPDM roof may outlast a poorly installed TPO roof, and vice versa.

Which Is Better for Different Commercial Building Types?

Warehouses

TPO is often preferred for large industrial spaces due to reflective properties and energy efficiency.

Retail Centers

TPO performs well where appearance and cooling costs matter.

Churches

EPDM is frequently selected for durability and flexibility.

Schools

Both systems are viable. Decision depends on budget and insulation design.

Industrial Facilities

If chemical exposure is present, system selection may shift toward specialized membranes. Professional evaluation is recommended.

When to Choose TPO Over EPDM

Choose TPO if:

-

Energy efficiency is a priority

-

The building has a large open roof surface

-

Reflective roofing supports operational cost reduction

-

Proper heat-welded installation is available

When to Choose EPDM Over TPO

Choose EPDM if:

-

The building experiences significant temperature fluctuation

-

Winter durability is the main concern

-

Long-term flexibility matters

-

Repair simplicity is important

Why Material Quality and Installation Matter

Membrane brand and supply quality influence performance.

Commercial-grade systems sourced through established manufacturers such as Malarkey Commercial Roofing provide:

-

Consistent membrane thickness

-

Strong seam systems

-

Weather-tested durability

-

Reliable warranties

However, even premium materials fail if installation is rushed or drainage design is flawed.

Professional installation and scheduled inspections extend roof life more than material choice alone.

Real-World Example in Lafayette

A Lafayette warehouse installed TPO on a 40,000-square-foot facility. After 15 years, regular inspections and minor seam maintenance kept the system fully functional.

Another commercial facility nearby chose EPDM for its ability to handle winter expansion and contraction. That roof surpassed 25 years with consistent upkeep.

In both cases, maintenance—not just material—determined longevity.

Commercial Flat Roofing in Lafayette, Indiana

Lafayette’s climate creates unique pressure on commercial flat roofs. Property owners across Tippecanoe County benefit from systems designed with:

-

Proper drainage slope

-

Seam integrity

-

Adequate insulation

-

Routine inspections twice per year

Selecting between TPO and EPDM should involve a professional roof evaluation rather than relying on material trends alone.

Wabash Valley Exteriors provides commercial roofing inspections, repair, and replacement services for warehouses, retail centers, churches, and industrial buildings throughout Lafayette and surrounding Indiana communities.

Frequently Asked Questions

Is TPO better than EPDM in cold climates?

EPDM generally handles cold climates better due to flexibility during freeze-thaw cycles. TPO performs well when properly installed but relies heavily on seam integrity.

How long does TPO last in Indiana?

TPO typically lasts 20–25 years in Indiana with routine maintenance and inspections.

How long does EPDM last in Indiana?

EPDM commonly lasts 20–30 years, particularly when maintained and inspected regularly.

Which commercial roof membrane costs more?

TPO often has a slightly higher installation cost. Long-term cost depends on energy savings and maintenance practices.

FAQs

Is TPO better than EPDM in cold climates?

EPDM typically handles extreme cold better due to its flexibility during freeze-thaw cycles.

Which commercial roof lasts longer in Indiana?

Both TPO and EPDM can last 20–30 years with proper installation and maintenance.

Does TPO reduce energy costs?

Yes. Its reflective surface helps reduce heat absorption on large commercial buildings.

Is EPDM cheaper than TPO?

EPDM often has a slightly lower initial material cost, but total cost depends on insulation and maintenance.

Final Decision: TPO or EPDM?

There is no universal answer.

Both systems perform well in Indiana when:

-

Properly installed

-

Professionally inspected

-

Maintained consistently

The right choice depends on your building, your budget, and your long-term facility goals.

If your commercial building in Lafayette or elsewhere in Indiana is due for evaluation, a professional inspection can determine which membrane system best fits your structure and operating environment.